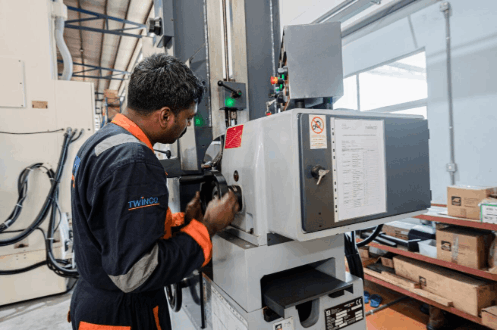

Field Services

Global Field Services – Anytime, Anywhere

Our In-Situ Machining and Diagnostic Services Include:

Camshaft Bore Machining

On-site machining of camshaft bores using the renowned Carl Baguhn B204 transportable tool with model-specific adapters.

Tappet Guide Machining

Restoration of worn tappet guides with repair liners. Machining is performed in-situ using alignment tools and replacement camshafts.

Cylinder Liner Seat Skimming

Repair of upper and lower liner seats to prevent gas or water leaks. If needed, oversize boring and fitting of cryogenically pre-treated repair liners.

Cylinder Liner Honing

Restoration of liner geometry using an adjustable honing head with a range of stones. Continuous monitoring of diameter and crosshatch pattern ensures precision and performance.

In-Situ Cylinder Liner Measurement

Fast and non-invasive liner wear measurements through scavenging ports – no need to remove cylinder covers. Compliant with requirements from classification societies and insurers.

Crankshaft Flange Skimming

Precision skimming using a portable surface grinder mounted directly to the flange. Performed without removing the crankshaft.

Hardness Testing (Brinell, Rockwell, Vickers)

Portable, non-destructive hardness testing to assess material integrity. Equipment is suitable for air travel and global deployment.

Crack Detection (MPI & DPI)

On-site inspection using:

Magnetic Particle Inspection – detects surface and slightly subsurface cracks using iron oxide in suspension and UV light.

Dye Penetrant Inspection – reveals surface defects through dye absorption and developer application.