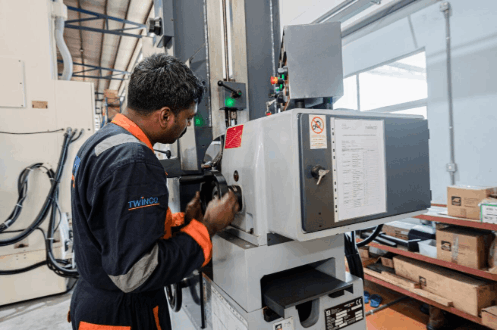

Twinco has been providing field services around the world for many decades. From Europe, Africa and Asia to Australia and the Americas – no distance is too great for our service teams. All year round, seven days a week, our mobile services are deployed from Singapore to a wide range of vessels and industries: ferries, cruise ships, container ships, tankers, bulk carriers, navy vessels, reefer ships, fishing trawlers, oil rigs, oil fabrication vessels, power stations at sea and on land, refineries, paper/fish/can factories and the offshore industry (for which Twinco technicians have the relevant safety qualifications).

The globally renowned B 204 transportable tool from Carl Baguhn is used for a range of applications, including in-situ machining of camshaft bores. The tool is installed on site using model-specific adapters and quickly aligned for use.

If tappet guides become pitted or scored, the original diameter can be restored using the appropriate repair liners. To prepare the required bore, the Twinco tool is aligned using the stud bolts and a replacement camshaft. The block is then bored and the prepared repair liners, made from the same material as the block, are inserted and secured.

Twinco can also repair cylinder liner seats. Water and gas leaks can be easily remedied through in-situ grinding or skimming. For this operation, an engine-specific adapter plate is mounted on the stud bolts and the Carl Baguhn tool is aligned with the existing seat surfaces. The surface is then ground or skimmed depending on the depth of the leakage source. If the upper or lower seat is too heavily corroded, the crankcase can be re-bored to an oversize diameter and fitted with repair liners pre-treated with liquid nitrogen.

SINGAPORE

No 3 Loyang Way 4, Singapore 506956

Tel.: +65 6542 9618.

Fax: +65 65427595 / +65 6545 7597

Email: sales@twinco.com.sg

CHINA

Tel.: +8621 5509 0063

Fax: +8621 5506 0227

INDONESIA

Tel.: +62 21 22608238

Tel.: +62 21 22604810

Fax: +62 21 22604945